Situated at our facility in Cleveland, Ohio, our abrasive Jet Edge Water Jet is a highly useful machine capable of rather intricate cuts in all sorts of materials. It effectively cuts using high pressured water combined with the abrasive material garnet. An important benefit of Water Jet machining is the ability to cut without affecting the material’s inherent properties.

Situated at our facility in Cleveland, Ohio, our abrasive Jet Edge Water Jet is a highly useful machine capable of rather intricate cuts in all sorts of materials. It effectively cuts using high pressured water combined with the abrasive material garnet. An important benefit of Water Jet machining is the ability to cut without affecting the material’s inherent properties.

Get a quote for machining your parts today.

Shipping to anywhere in the USA.

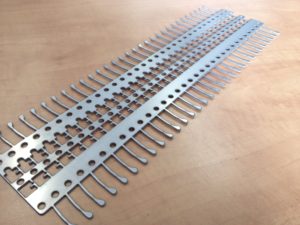

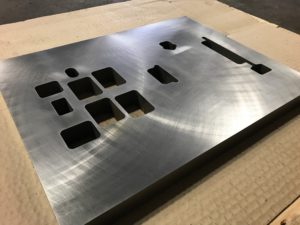

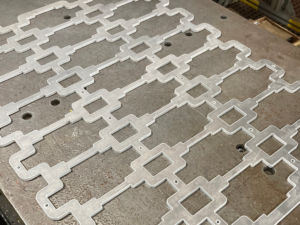

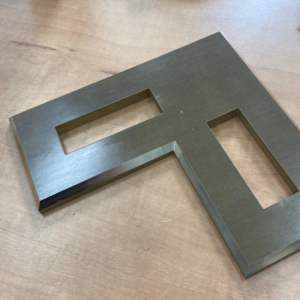

Our high-powered Water Jet cutting system offers a 4 ft. x 8 ft. cutting area and can cut steel 6+ inches thick. It is highly suitable to cut a broad spectrum of materials, including ferrous and non-ferrous metals: steel, hardened tool steel, aluminum, stainless steel, titanium, copper, brass, bronze, nickel, iron, and magnesium. It can cut all sorts of polymers (plastics, Delrin, plexiglass, rubber), and even materials like glass, foam, stone, MDF, and friction materials.

We can provide you with cut parts + any additional machining that your parts may require. It is common for us to machine features after Water Jet cutting such as milling pockets, reaming holes, and tapping holes.

We can work with 2D or 3D CAD files, prints, drawings, and even sketches. We will provide the best nesting options to maximize material yield and reduce costs.

Water jet cutting is great for simple and complex features. Types of products produced by Water Jet cutting include:

- Plates

- Panels

- Covers

- Brackets

- Gaskets

- Templates

- Fixtures

- Gussets

- Bolster Plates

- Stripper Plates