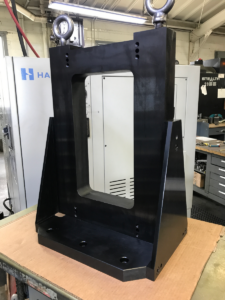

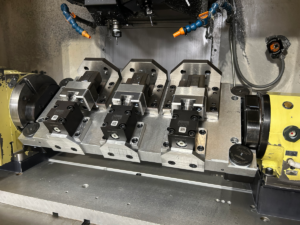

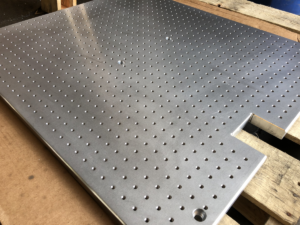

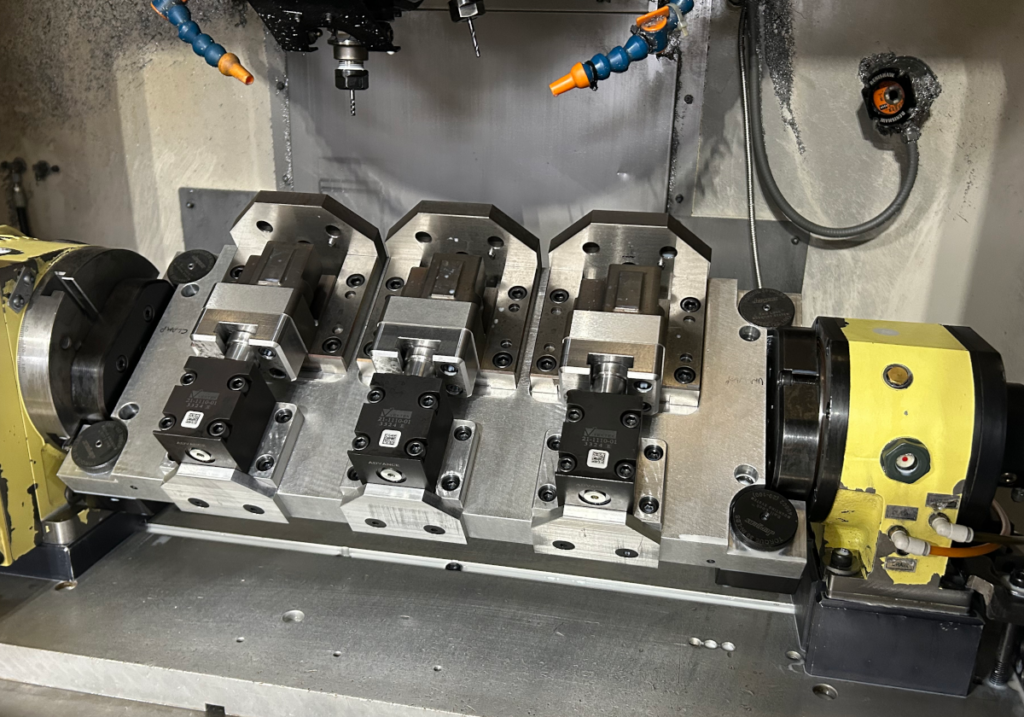

Trim Tool & Machine produces custom turnkey systems with leading manufacturers. We provide full 3D CAD design and build of custom CNC machining fixtures to fulfill your machining requirements. We have designed and built fixtures for castings, stampings, extrusions, forgings, and mill blanks. Custom workholding options include trunnion-style, internal hydraulic clamping, quick-change, air part seat detect, robot load & unload, and poka-yoke mechanisms. Clamping styles include manual, pneumatic, hydraulic, and sometimes a combination.

Contact us today to begin discussing your tooling requirements.

We can provide a custom fixturing solution for 3-axis, 4-axis, and 5-axis machining center projects. In addition to all of the vertical mill tooling, we build tombstones for horizontal CNCs and custom fixturing, jaws and collets for CNC lathes. Trim Tool & Machine will provide the proper support to get your equipment and tooling running effectively and efficiently.

The following images are a sample of machining fixtures and fixture plates built by us: